The high-quality dock levelers that we offer have been proven over the years to be some of the strongest and most reliable levelers on the market, providing a smooth and efficient loading process. Our dock levelers can be activated automatically or mechanically and are available as pit-style, edge-of-dock or vertical storing. Each leveler type comes in a variety of sizes and capacities to meet any loading dock application requirement.

HYDRAULIC DOCK LEVELERS

Hydraulic dock levelers are push-button activated and allow high capacity ratings when required. They utilize fully powered raise and lip extension functions with hydraulic cylinders and hydraulic pump and motor stations. Hydraulic levelers are considered the safest loading dock choice and have more available options than any other activation type.

AIR POWERED DOCK LEVELERS

Air-powered dock levelers are an economical alternative to hydraulic levelers, but are still operated with a push-button activation for ease of use. They have a mid-range capacity with an air bag system used to raise and lower the deck. This is a great solution where push button activation is desired along with low maintenance.

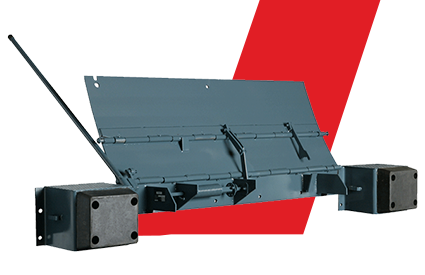

MECHANICAL DOCK LEVELERS

Mechanical levelers use a pull chain activation to raise the deck. The operator simply walks the deck back down to the bed of a trailer or to a stored position. These levelers range from low to mid capacity ratings and are a great entry product where pit type dock levelers are required.

LOADING DOCK LEVELERS

The high-quality dock levelers that we offer have been proven over the years to be some of the strongest and most reliable levelers on the market, providing a smooth and efficient loading process. Our dock levelers can be activated automatically or mechanically and are available as pit-style, edge-of-dock or vertical storing. Each leveler type comes in a variety of sizes and capacities to meet any loading dock application requirement.

HYDRAULIC DOCK LEVELERS

Hydraulic dock levelers are push-button activated and allow high capacity ratings when required. They utilize fully powered raise and lip extension functions with hydraulic cylinders and hydraulic pump and motor stations. Hydraulic levelers are considered the safest loading dock choice and have more available options than any other activation type.

AIR POWERED DOCK LEVELERS

Air-powered dock levelers are an economical alternative to hydraulic levelers, but are still operated with a push-button activation for ease of use. They have a mid-range capacity with an air bag system used to raise and lower the deck. This is a great solution where push button activation is desired along with low maintenance.

MECHANICAL DOCK LEVELERS

Mechanical levelers use a pull chain activation to raise the deck. The operator simply walks the deck back down to the bed of a trailer or to a stored position. These levelers range from low to mid capacity ratings and are a great entry product where pit type dock levelers are required.

EDGE OF DOCK LEVELERS

MEDLF Mechanical EOD Leveler

The MEDLF Series edge-of-dock leveler is a light duty low-cost alternative to the a pit style dock leveler where the trailer height and warehouse floor height delta is 3″ or less. Operation is a two-step process with a “lift free” handle to place the unit in the trailer.

Features

- Superior Structural Criteria in an Edge of Dock Leveler

- Easy to Operate “Lift Free” EOD

- Reliable Operation That is Comparatively Stress Free

- Automatic Return to Stored Position Once Trailer Departs

HED Electronic EOD Leveler

The HED Series edge-of-dock levelers represent a low cost hydraulically operated unit that bridges the gap between building and truck where a minimal variance exists between dock and truck. Once trailer pulls away unit automatically stores and if trailer stays at dock unit can be stored hydraulically without the need to move trailer.

Features

- Superior Structural Criteria in an Edge of Dock Leveler

- Automatic Return to Stored Position Once Trailer Departs

- Full Hydraulic Operation

- Smooth and Consistent Operation of Your EOD

EDGE OF DOCK LEVELERS

HED Electronic EOD Leveler

The HED Series edge-of-dock levelers represent a low cost hydraulically operated unit that bridges the gap between building and truck where a minimal variance exists between dock and truck. Once trailer pulls away unit automatically stores and if trailer stays at dock unit can be stored hydraulically without the need to move trailer.

Features

- Superior Structural Criteria in an Edge of Dock Leveler

- Automatic Return to Stored Position Once Trailer Departs

- Full Hydraulic Operation

- Smooth and Consistent Operation of Your EOD

MEDLF Mechanical EOD Leveler

The MEDLF Series edge-of-dock leveler is a light duty low-cost alternative to the a pit style dock leveler where the trailer height and warehouse floor height delta is 3″ or less. Operation is a two-step process with a “lift free” handle to place the unit in the trailer.

Features

- Superior Structural Criteria in an Edge of Dock Leveler

- Easy to Operate “Lift Free” EOD

- Reliable Operation That is Comparatively Stress Free

- Automatic Return to Stored Position Once Trailer Departs

VERTICAL DOCK LEVELERS

Vertically storing hydraulic dock levelers are unique and are installed at facilities where temperature control and cleanliness are high priorities. These are typically used in Food & Beverage, Pharma or High End Manufacturing Facilities. The vertical storing design provides the tightest environmental seal when not in use. The push button activation offers convenience while providing smooth, consistent operation combined with outstanding toughness and dependability. These can be installed in either a single pre-formed pit or a longer shelf style pit for multiple units. Various sizes and capacities allow for a large amount of flexibility.

VERTICAL DOCK LEVELERS

Vertically storing hydraulic dock levelers are unique and are installed at facilities where temperature control and cleanliness are high priorities. These are typically used in Food & Beverage, Pharma or High End Manufacturing Facilities. The vertical storing design provides the tightest environmental seal when not in use. The push button activation offers convenience while providing smooth, consistent operation combined with outstanding toughness and dependability. These can be installed in either a single pre-formed pit or a longer shelf style pit for multiple units. Various sizes and capacities allow for a large amount of flexibility.

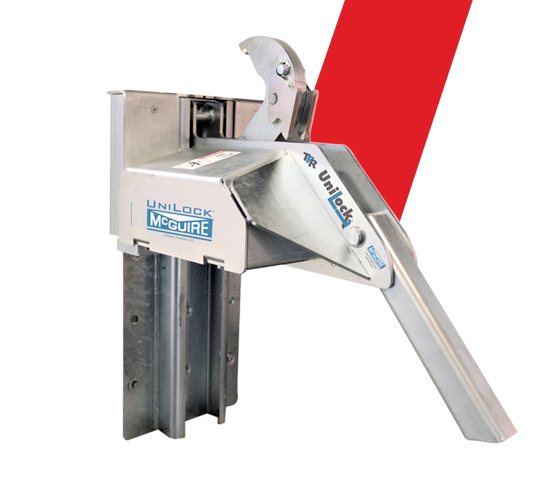

TRUCK RESTRAINTS

The warehouse and loading dock areas account for most of the injuries inside an industrial facility. Many forklift accidents occur every year that are caused by a truck prematurely departing from the dock or creeping away due to loading and unloading momentum. Our Truck Restraints will help prevent these accidents by securing a trailer to the dock and while providing communication between the truck driver and dock attendant. We have many activation types and designs to fit your application and budget.

DOCK SEALS & SHELTERS

We offer a variety of dock seals and shelters designed to seal the gap between the truck trailer and the building wall. Dock Seals & Shelters keep your temperature controlled air inside your facility and the ambient air from entering your building. They also greatly help safety at your loading dock by keeping the dock leveler dry during loading and unloading operation.

LOADING DOCK ACCESSORIES

We also provide and install many loading dock accessories such as: Dock Lights, Dock Fans, Stand Alone Light Communication Systems, Track Guard and Railing, along with many other products to help your loading dock needs.

SECTIONAL, ROLLING SERVICE & FIRE DOORS

We offer many types and designs of industrial doors for whatever your application calls for. The EntreDock team can review your application requirements to see what door type best suits your facility. Along with standard doors, we have many upgrade options to help reduce maintenance such as flexible sections, heavy duty track, high cycle springs.

HIGH PERFORMANCE DOORS

High performance doors, also known as “High Speed Doors” are used for many different applications where high cycles and high performance are required. These doors open and close automatically and quickly for temperature control, environmental or security.

HIGH VELOCITY LOW SPEED (HVLS) FANS

HVLS Fans slowly circulates the warehouse air providing a more comfortable environment and air quality reducing the temperature by as much as 15 degrees. They also lower heating and air conditioning costs in warehouses that are temperature controlled.

LOADING DOCK ACCESSORIES

We also provide and install many loading dock accessories such as: Dock Lights, Dock Fans, Stand Alone Light Communication Systems, Track Guard and Railing, along with many other products to help your loading dock needs.

DOCK SEALS & SHELTERS

We offer a variety of dock seals and shelters designed to seal the gap between the truck trailer and the building wall. Dock Seals & Shelters keep your temperature controlled air inside your facility and the ambient air from entering your building. They also greatly help safety at your loading dock by keeping the dock leveler dry during loading and unloading operation.

TRUCK RESTRAINTS

The warehouse and loading dock areas account for most of the injuries inside an industrial facility. Many forklift accidents occur every year that are caused by a truck prematurely departing from the dock or creeping away due to loading and unloading momentum. Our Truck Restraints will help prevent these accidents by securing a trailer to the dock and while providing communication between the truck driver and dock attendant. We have many activation types and designs to fit your application and budget.

HIGH VELOCITY LOW SPEED (HVLS) FANS

HVLS Fans slowly circulates the warehouse air providing a more comfortable environment and air quality reducing the temperature by as much as 15 degrees. They also lower heating and air conditioning costs in warehouses that are temperature controlled.

HIGH PERFORMANCE DOORS

High performance doors, also known as “High Speed Doors” are used for many different applications where high cycles and high performance are required. These doors open and close automatically and quickly for temperature control, environmental or security.

SECTIONAL, ROLLING SERVICE & FIRE DOORS

We offer many types and designs of industrial doors for whatever your application calls for. The EntreDock team can review your application requirements to see what door type best suits your facility. Along with standard doors, we have many upgrade options to help reduce maintenance such as flexible sections, heavy duty track, high cycle springs.

BEST VALUE

We plan to not only be competitively priced, but we plan to provide the best overall value to each of our customers. If you haven’t worked with us, please consider giving us an opportunity on your next project.